Gear Hobs

Gear hobbing is a distinctive process that differs from milling in that both the cutting tool and the workpiece move in a precise synchronization to create the desired cut. Gear hobbing is a popular process for cutting splines and sprockets, as well as creating spur and helical gears.

Integrated Components uses gear hobbing technology to manufacture splines on an array of shafts, in addition to a number of other applications. The process of gear hobbing is perfect for cutting shafts in one pass without spline relief and can be repeated with excellent precision, making it a reliable and fast method for shaft and gear production.

Integrated Component’s gear hob meets the diverse requirements of our customers with quick and accurate reliability.

Barber Colman

Integrated Components uses gear hob technology to manufacture splines on an array of shafts. This technology is perfect for cutting shafts without spline relief in one pass with excellent repeat-ability. Integrated Components has a large selection of gear hob cutters for a variety of applications.

Advanced Aircraft Gear Hob Machines in the Midwest

Integrated Components is committed to provide only the top-notch, precision product our customers require. We regularly invest in our company to further enhance our team’s ability to produce the best aircraft parts in the region.

New Gear Hobbing Technology

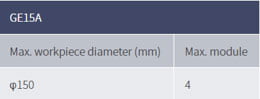

One of the new machines working to make precision aircraft parts at our facility is the Nidec GE15A. This is a gear hobbing machine manufactured by Nidec Machine Tool Corporation.

Midwest’s Most State-of-the-Art Aircraft Parts Technology

Integrated Component’s acquisition of this Nidec gear hobbing machine represents an investment unique to the Midwest. With the installation of this equipment and a new gear shaping machine, Integrated Components is the only company in over the past 3 decades to have purchased new gear cutting machines in the region.

Armed with these new high-tech manufacturing machines, Integrated Components has expanded our capabilities to include helical, crown, and other specialty gears.